Hot rolled steel is steel that has been heated above its recrystalization point and is pushed between two rollers to meet a certain length and thickness.

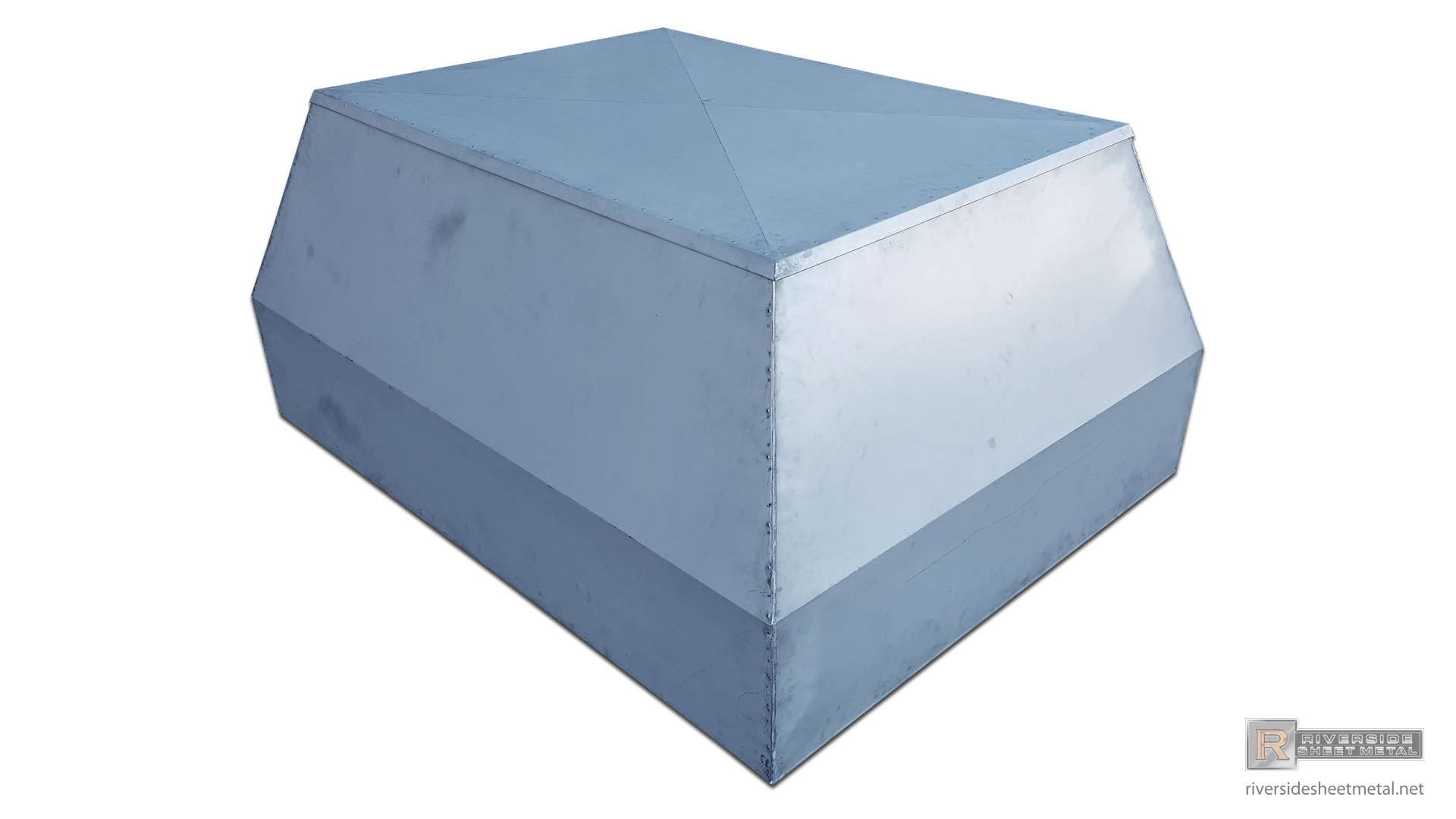

Galvannealed steel sheet for countertops.

Meets astm a653 09 specifications requirements.

In comparison to galvanized steel the coating is harder and more brittle.

This allows for the galvannealed steel to be more ductile and flexible.

It is vastly used for many miscellaneous applications.

Galvannealed steel hot dip zinc iron coated structural steel annealed with guaranteed minimum yield strength.

Galvannealed steel has a matte grey color uniform which can be easily painted.

Galvannealed steel is a matte uniform grey color which can be easily painted.

Class 1 mechanical properties chemical composition.

Steel base guaranteed typical range guaranteed maximum percent longitudinal tensile carbon c 0 25 yield strength minimum ksi 80 80 117 phosphorus p 0 04 tensile strength minimum ksi 82 82 120.

The steel is then annealed which converts the zinc into a zinc alloy coating that offers increased corrosion and scratch resistance.

This is preferred over galvanized if the metal is to be painted.

Avoid painted metal degradation with resilient galvannealed steel sheet and coil products from alliance steel.

In comparison to galvanized steel the coating is harder and more brittle.

Has no protective film.

Galvannealed steel has very similar properties as standard galvanized but the surface has a more porous and abrasive finish that more readily accepts paint.

May have minor scratching.

Galvannealed steel grade data sheet.

Galvannealed or galvanneal galvannealed steel is the result from the processes of galvanizing followed by annealing of sheet steel.

.jpg)